Class part of a nationwide pilot program

In a new course offered this academic year at Catholic High School, Virginia Beach, it’s the students who are doing the testing.

“Engineering for Us All,” a national pilot program developed by the University of Maryland, aims to teach students the principles of engineering by allowing them to put them into practice.

“The course is almost exclusively project- based,” said CHS physics instructor William Silkman, a retired Naval engineer. “It’s all about taking the students through the process. They are given an engineering problem, and then they present their solutions.”

Throughout the year, the students have been learning what it means to be an engineer by embarking upon a variety of projects — from building portable water filters to designing rain shelters — using materials such as coat hangers, paper and aluminum foil.

For each project, they work step-by-step though the engineering process: they develop designs, build prototypes, and then test, evaluate and make improvements on their creations.

“It’s definitely a lot more hands-on than other classes,” said senior Joey Kagel. “You can’t really test and try out different ideas otherwise.”

While it’s the first year the class has been offered at Catholic High, it’s the second year nationwide. Nineteen students are enrolled in the class, which is open to grades 10 through 12.

Students who opt to take the course online or who are self-quarantining are provided with kits containing supplies to complete projects at home.

Real world problems

The students began their study, Silkman said, with a lesson on what engineering is and how it is everywhere in the world—everything from the soles of shoes to skyscrapers.

“Early in the semester, I had them bring in anything that was broken,” he said. “Small appliances, stereos, coffee makers — anything that no one was going to use anymore. And then we took them apart, to see how they worked.”

The class was interested in taking a behind-the-

scenes look at what is at our fingertips, every day, he said, “particularly in all of the ways methods of storing music have changed over just the past few decades.”

The course endeavors not only to show students that there is inherent design in everything, Silkman said, but also to give them a larger, global perspective by focusing on such issues as clean drinking water, recycling, sustainability and environmental stewardship.

So far this semester, the students have tried their hand at creating robotic arms designed to lift containers of simulated hazardous waste and at designing shoes affordable enough to be made in bulk for those living in developing countries.

Shawn Newnan, a junior, explained that for the shoe project, his group designed a steel-toed sandal made of rubber.

“Part of the plan was that they would already have rubber there, in old tires,” he said. “Using the tires would keep shipping costs down and would be a way of reusing old materials.”

Matt Norman, also a junior, said one of the most unique challenges the class has tackled has been to design an efficient rain shelter made largely from paper.

How is it possible to make a paper shelter waterproof?

“Duct tape,” sophomore Avery Allenburg said.

Clear solutions

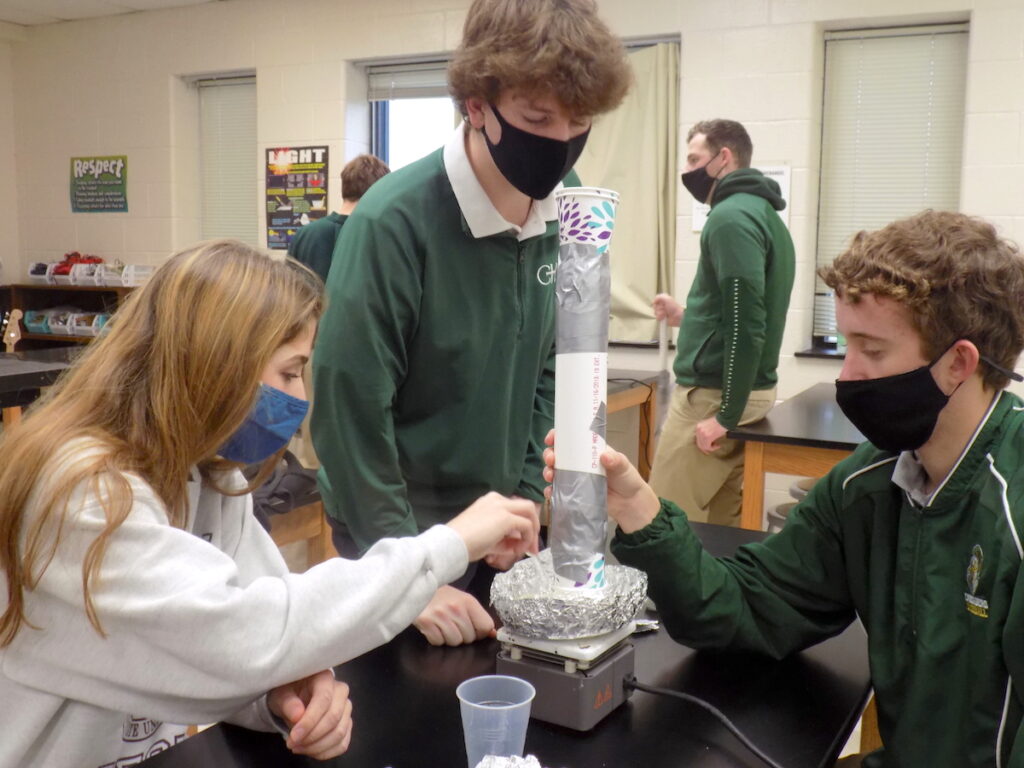

The students’ most recent project involved building portable water filters suitable for a three-day camping trip. Their task: to create a filter that would be light enough to carry, but which would be able to process at least 5.7 liters over the course of the trip.

The class split into four groups — each building a different filter with its own unique features — using PVC pipe, duct tape, pencils, rocks, sand and activated charcoal. After testing the filters, the students found that they yielded mixed results.

So, on an overcast Wednesday morning, they took their inventions back to the drawing board in order to make improvements to their designs.

As the four groups got to work, Silkman handed out cups of contaminated water — a mixture of water, vinegar, food coloring and dirt. “

It looks pretty bad,” Newnan confirmed, as he poured the water into the top of his group’s filter.

Meanwhile, seniors Patrick Davey and Zack Bromley — both of whom said they hope to major in engineering in college — worked on a filter in which a section of PVC pipe filled with sand, rocks and activated charcoal hung from a handle like a pendulum.

“The idea was that by swinging the filter, you could make the water move through it faster,” Bromley said.

Across the room, Kagel worked on a filter that used the distillation process, adjusting the angle of a section of PVC pipe leading to an aluminum- foil container on a hot plate before affixing it generously with duct tape.

Then he stepped back, watching it appraisingly, as a pipe leading from the bowl began to emit steam into a plastic bag.

“It’s working a little better now,” he said.

Once the students had collected samples of filtered water, Silkman passed out pH testing strips so that they could begin assessment of their final product.

“We’re really glad that we were able to offer the class,” Silkman said. “It’s not the sort of course you can teach entirely online, without that hands-on component, and do it justice.”

“It’s fun. I’ve been enjoying it,” Newnan said. “Not every design works, but that’s all a part of the class.”